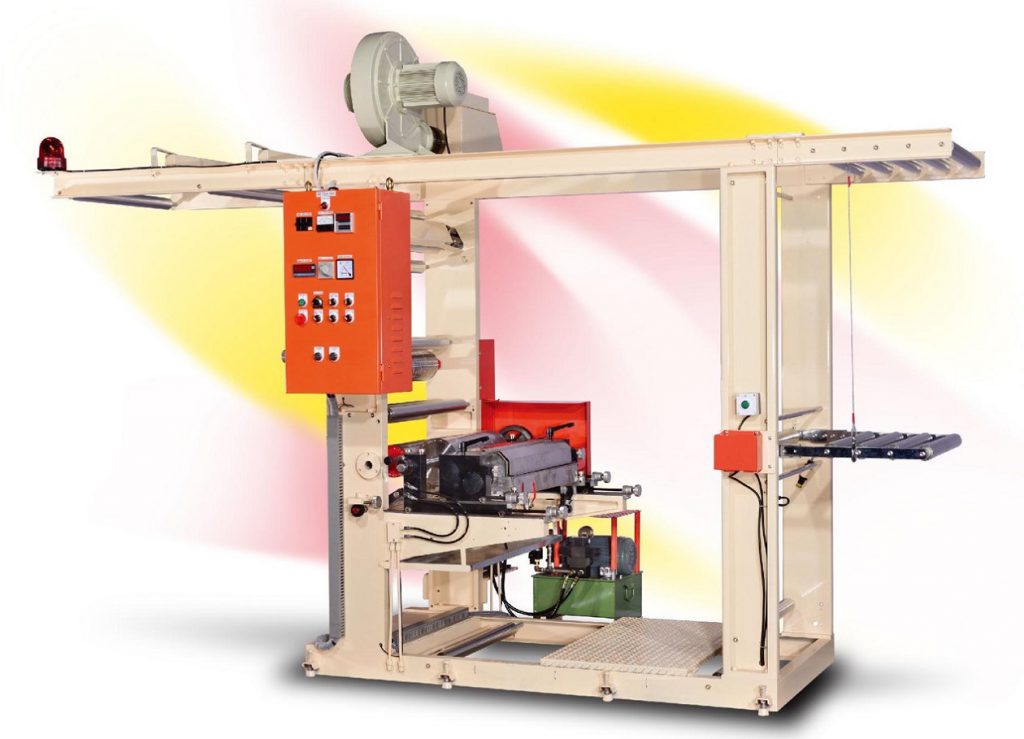

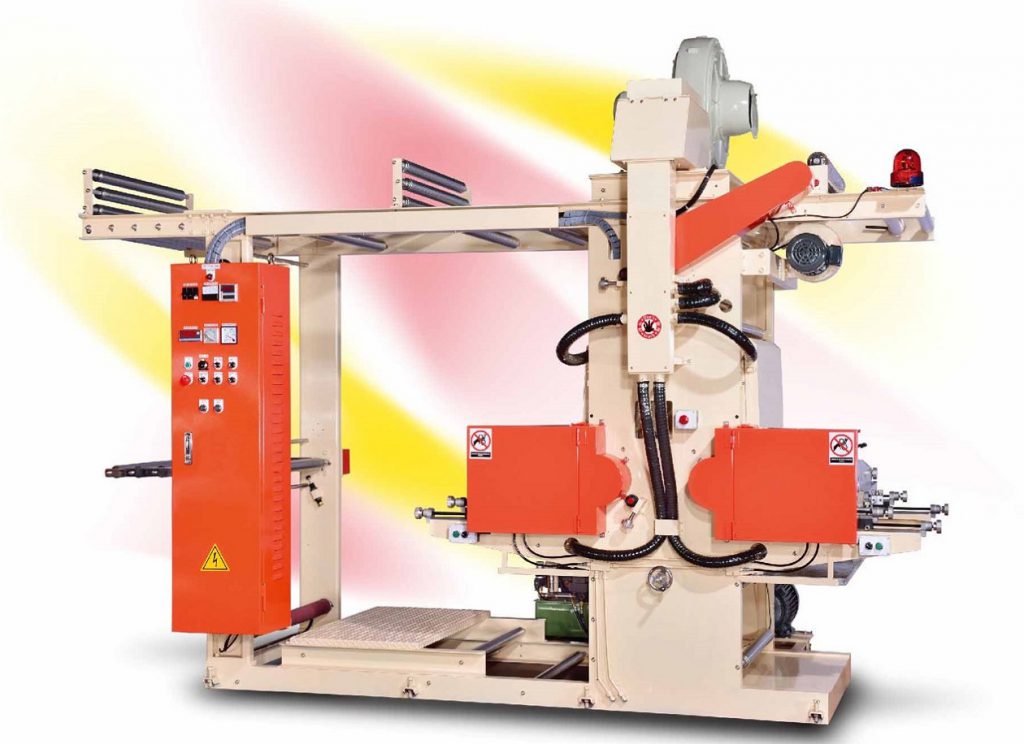

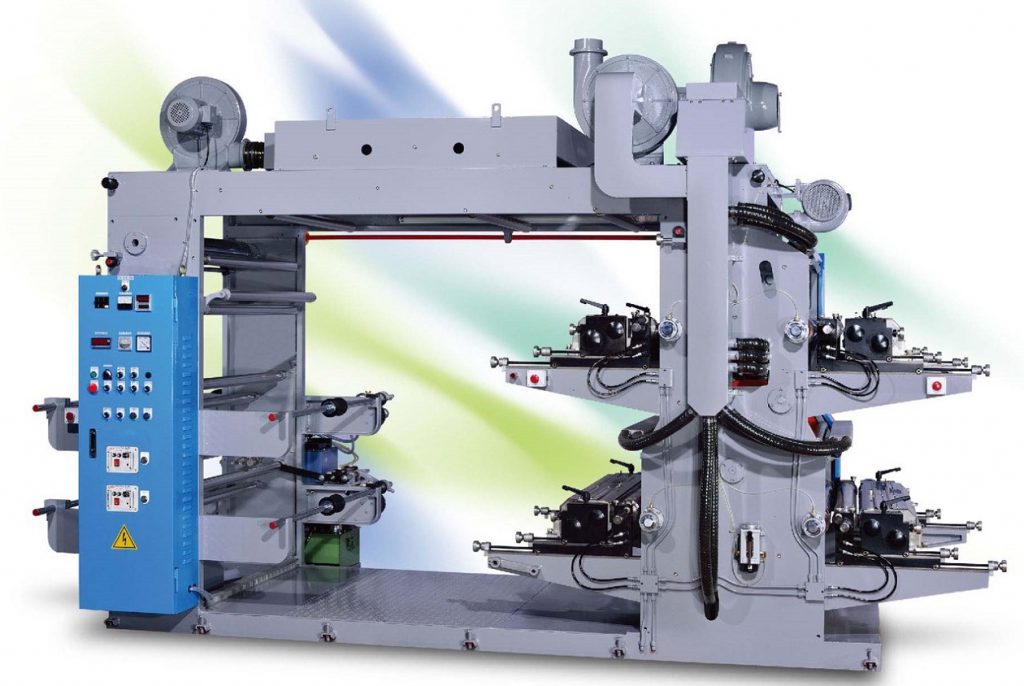

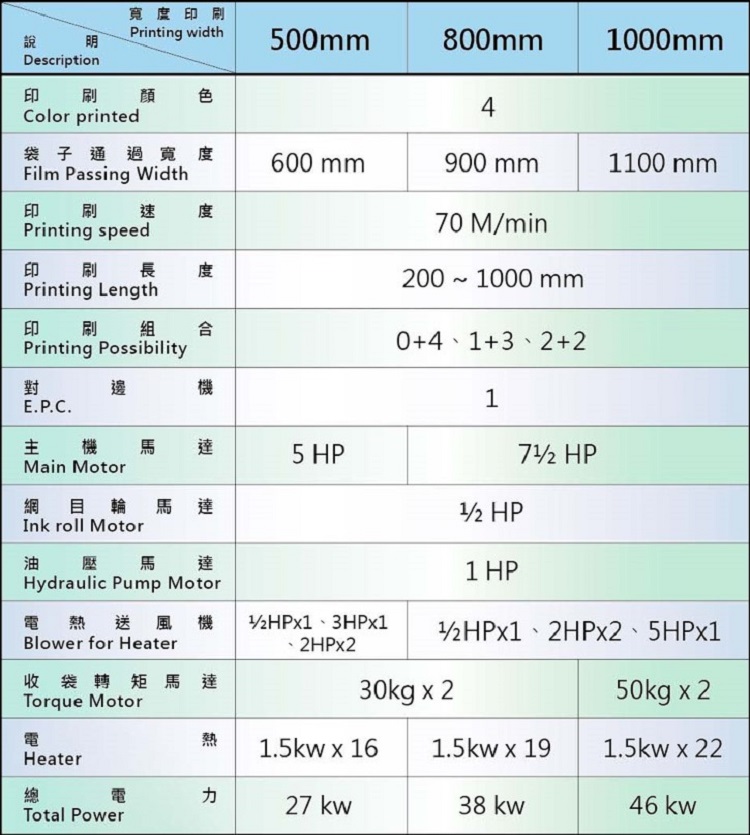

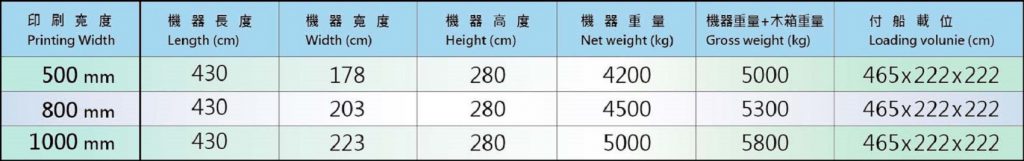

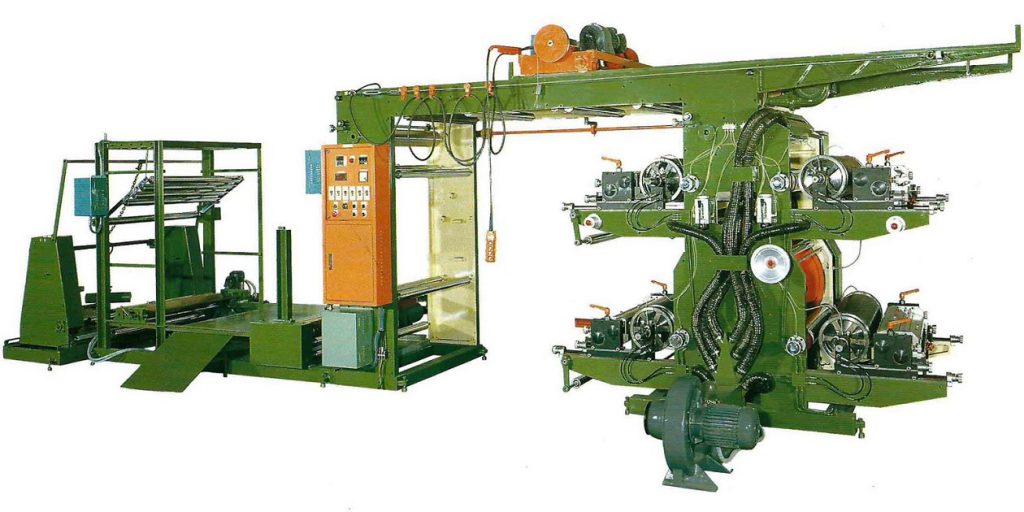

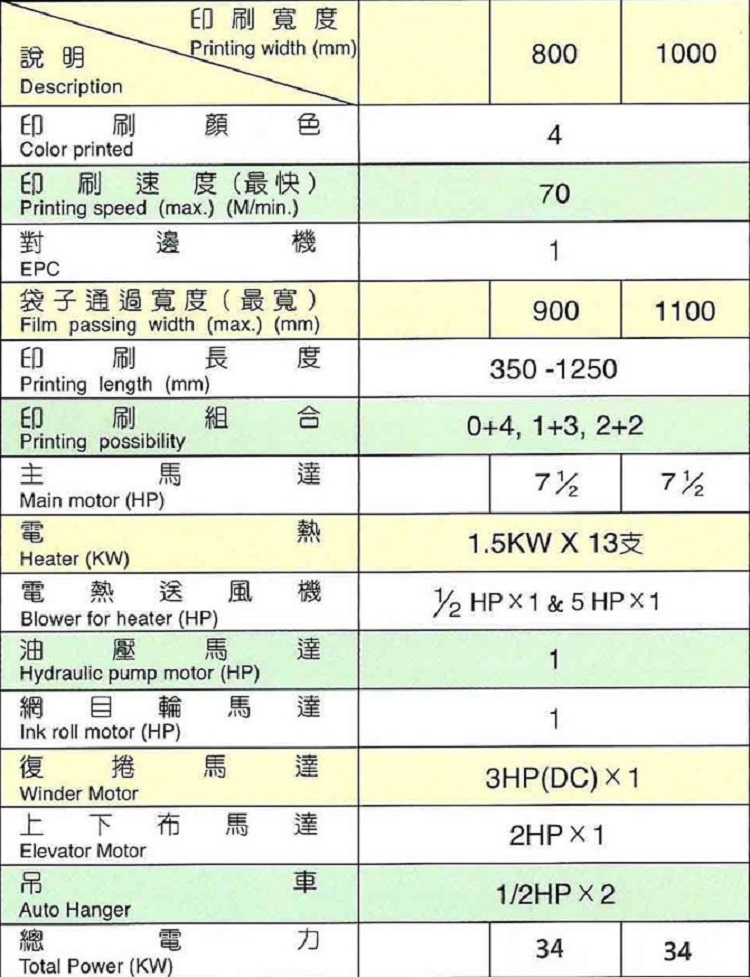

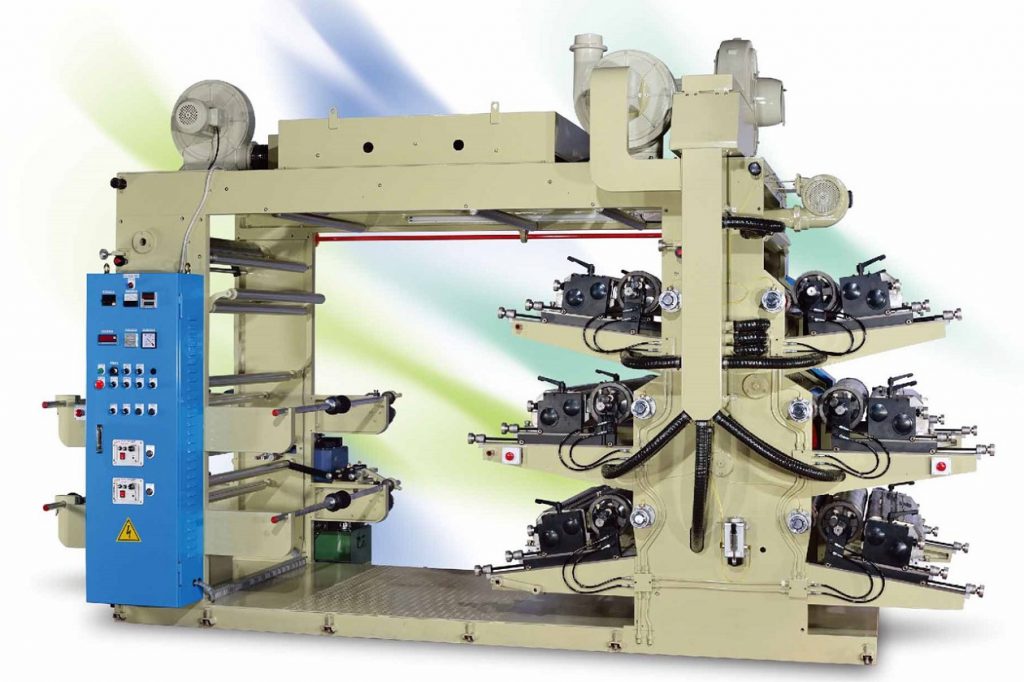

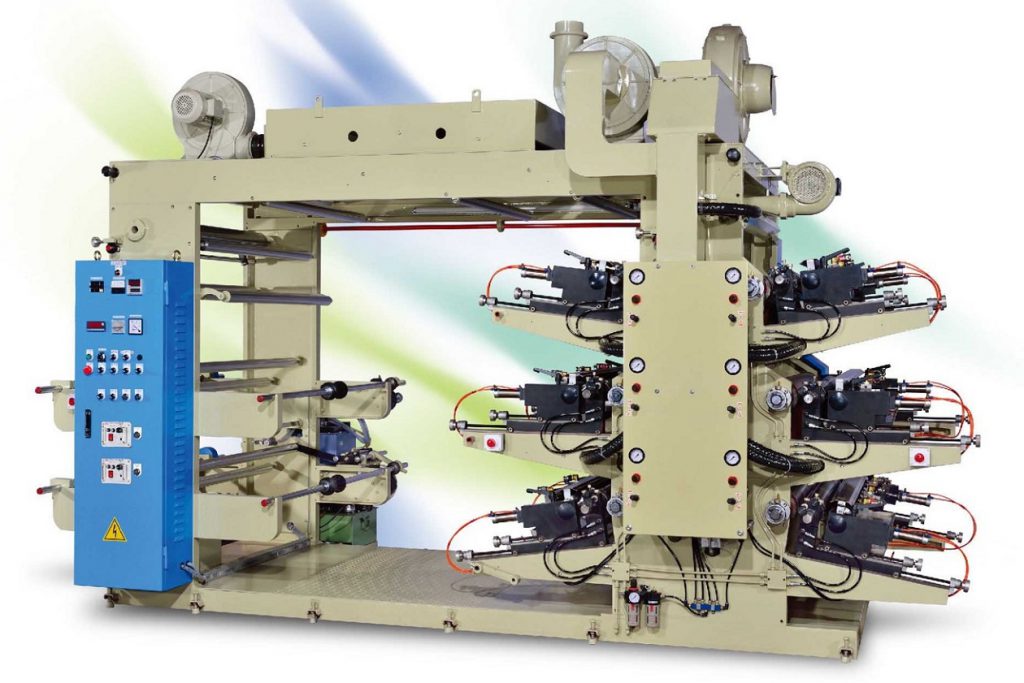

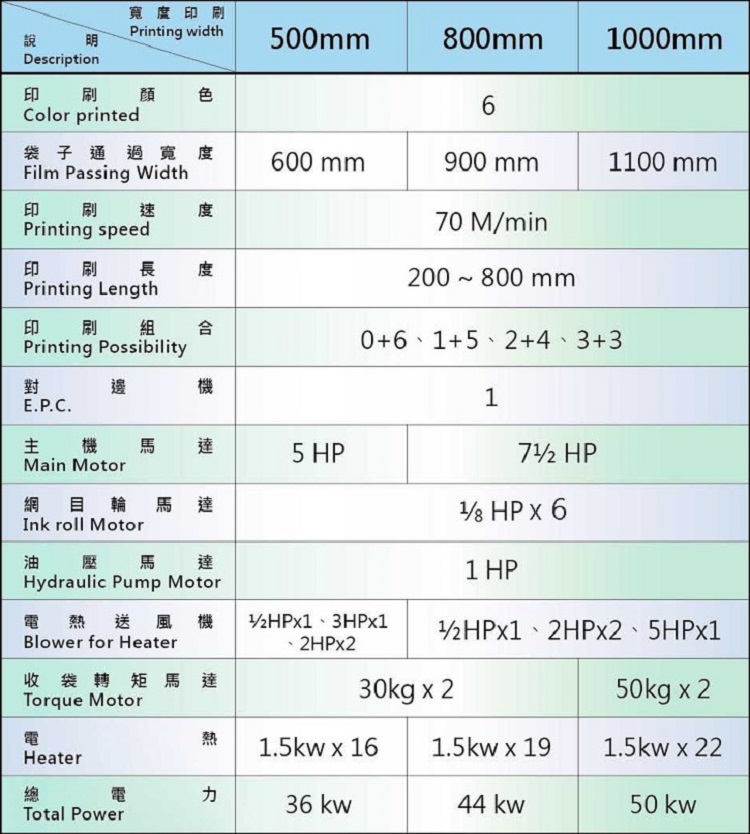

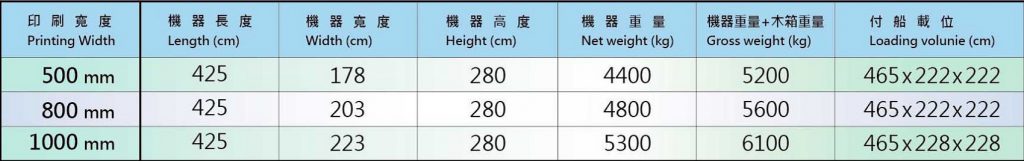

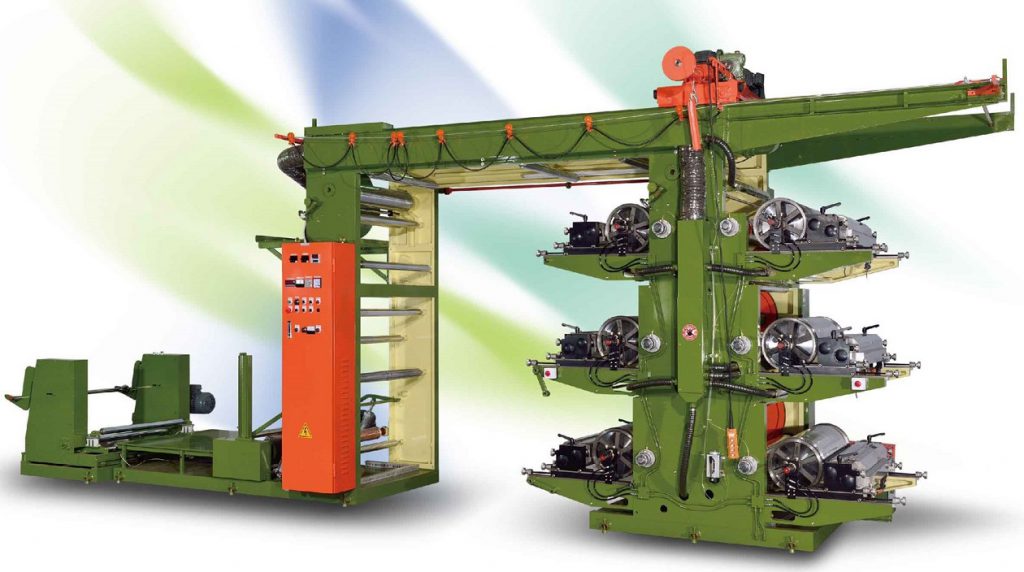

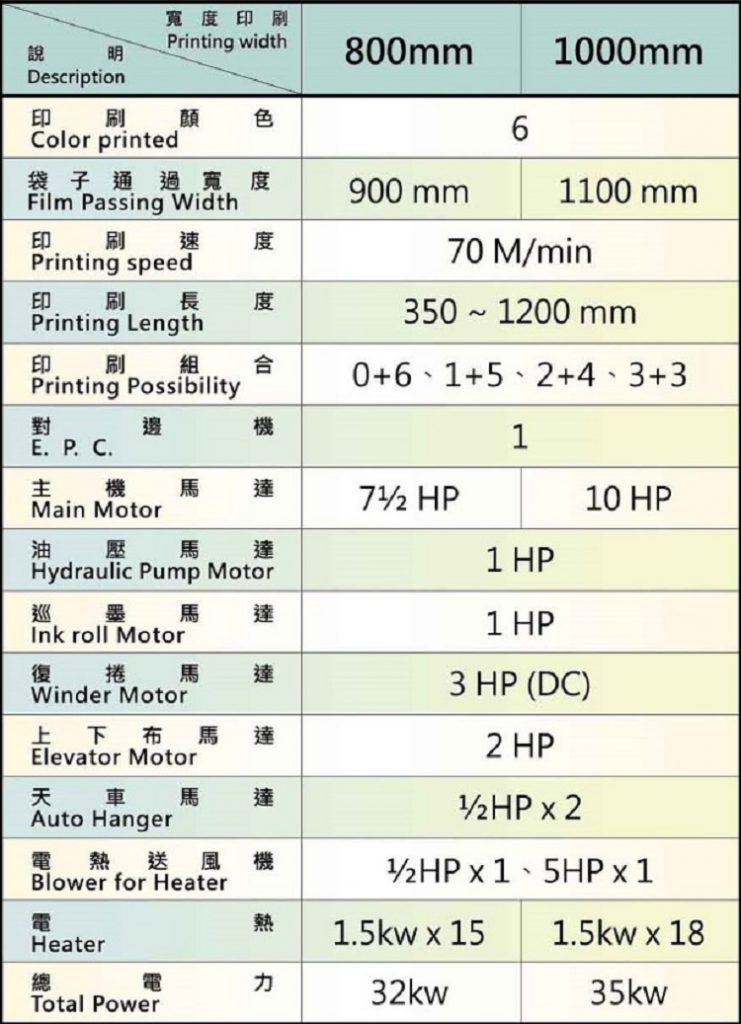

CHARACTERISTICS OF TG SERIES

FLEXOGRAPHIC PRINTING MACHINE

- This Machine is suitable for printing paper, glass paper, P.P. and P.E. bags.

- Compact size with rigid construction enhances productivity.

- Using hydraulic system to set the printing plates, it is easy and accurate in operation. There will be no defects when starting and stopping of the machine.

- The built-in impression counter can stop the machine automatically when the desired quantity of prints is acquired, and starts again on reset.

- The throw-off or on action of printing cylinder is hydraulically operated.The interlocking mechanism keeps the inking rolls running to avoid drying of ink on such rolls, accomplishing the throw-off of printing cylinder.

- Using a hot-air dryer and a cold-air fan simultaneously, it makes the production more speedly. The dryer and fan will shut down automatically when the machine stops. It makes this machine more safe.

- The built-in device stops the machine automatically.